1. Test overview.

This test is used to verify that the principal belt of the film Slide carrier is sufficiently tightened. This test is similar in its operation with that of MOTOR INTENSITY. The latter having been done previously, the primary tension belt by is consequently correct . If the test slide motor intensity fails, this means that the film carrier has a problem.The software measures always the current sent to the motor, which represents the image of the tension of the belt: the more the belts are tightened, the greater the effort to make the motor turn, therefore the more current will be needed.

The advance of film during the scan must be maintained as steady as possible. Also, the software controls the current sent to the motor in relation to the efforts needed . The current thus must be as steady as possible, however, variations can happen due to the " off centred effect " of the gears.

The measurement of the tension of the belt is made for both directions of the motor (corresponding to the pre scan and the scan).

If the belt of the film carrier is not sufficiently tightened, the film may slip during the scan and that can generate an incorrect framing of the images. On the other hand, if the belt is overtightened, the risk of overtorque (overloaded motor) will increase.

2. Test conditions.

This test relates to the Mounted slide gate inserted in the scanner.The Mounted slide gate must be inserted in the scanner to carry out this test.

No slide is necessary for this test.

The acceptance of the test is automatic.

No parameter is saved.

3. Pre-requirements.

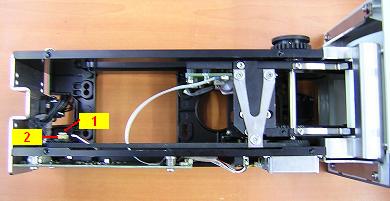

To make this test, it is necessary to mechanically tightened the belt of the film carrier . This can also be done manually.Remove the protective plate of the film carrier (the belt becomes visible). Loosen the lock-nut (1) (at the back of the film carrier). Tighten or slacken the belt while operating the eccentric (2) (at the back of the lock-nut until finding the correct tension). Tighten the lock-nut (1) and launch the test in order to check that the tension is correct . In general, you know that the tension is correct by putting the film carrier vertically and by seeing that the Slide Switch Zero charriot is in extreme case of balance.

4. Test realisation.

Click on RUN to execute the test. The motor will turn during 3 seconds in one direction then 3 seconds in the other direction (these 3 seconds correspond to a complete movement of the Slide carrier).At the end of the test, in the Result window, a red and a blue curves will be displayed (corresponding to both directions of rotation of the test). In the execution window, quantified results of each curve will be displayed .The test will automatically be accepted or rejected according to Results of these 2 curves.

5. Test acceptance.

The software is mainly used for 3 criteria (for each direction of rotation, that is to say 6 in total) to accept or reject the test:- the average of the curve.

- the maximum of the curve.

- minimum of the curve.

6. Other affected tests.

If the tension of the belts of the film Slide carrier is modified in significant proportions, the following tests should be remade:- slide cal play.

- slide cal encoder 2.

- slide cal Autofocus Position.

- slide cal RGB IR.