1. Test overview.

This test is used to check that the belts of the 135 Film carrier is sufficiently tightened. This test is similar in its operation to that of MOTOR INTENSITY. This one having been made as a preliminary, the primary tension belt is consequently correct. If the test 135 motor intensity fails, this means that it is the film carrier which is involved.The software thus measures always the current sent to the motor, which represents the image of the tension of the belts: the greater the belts are tightened, the more effort is required to turn the motor, therefore the greater current output necessary.

The advance of film during the scanning must be maintained the most lightly as possible, as the software regulates the current sent to the motor according to the efforts needed . Therefore the current must be as stable possible, however, some variations can happen due to the off centred effect effect of the gears.

The measurement of the tension of the belts is made in both directions of the motor (corresponding to the pre-scanning and of the scanning).

If the belts of the film carrier are not sufficiently tightened, the film can slip during the scanning and this can generates a incorrect image framing. On the other hand, if the belts are overtightened, the risk of overtorque (overloaded motor) will become greater.

2. Test conditions.

This test relates to the 135 Film carrier inserted in the scanner.The 135 Film carrier must be inserted in the scanner to carry out this test.

No film is necessary for this test.

The acceptance of the test is automatic.

No parameter is saved.

3. Pre-requirements.

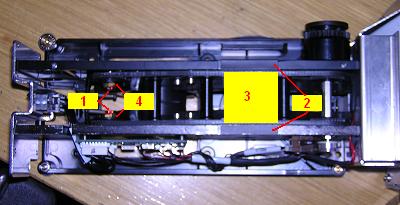

Prior to doing this test, it is necessary to mechanically tighten the 2 belts of the film carrier using normally a tension checker tool, but it can be done by hand. See paragraph 1.3.2.2.- If the tool is available : Remove the protective plate of the film carrier (the belts become visible). Loosen the lock-nut (1) (at the back of the film carrier). Take out the antiflare plates (2). Place the tool between the lower and higher plate (3), then press on the belt using the comparator. Tighten or slacken the belt while operating the eccentric (4)(behind the lock-nut). When the correct tension is found, tighten the lock-nut (1).

- Proceed the same with the other belt.

- If the tool is not available : Remove the protective plate of the film carrier (the belts become visible). Loosen the lock-nut (1) (at the back of the film carrier). Take out the antiflare plates (2). Tighten or slacken the belt while operating the eccentric (4) (behind the lock-nut) until finding the correct tension. Proceed the same way with the other belt. Tighten the lock-nut (1) and launch the test in order to check that the tension is correct.

4. Test realisation.

Click on RUN to carry out the test. The motor will turn during 15 seconds in one direction then 15 seconds in the opposite direction (this 15 seconds correspond to a revolution of film carrier belt .At the end of the test, in the result box, a red and blue curves will be displayed (corresponding to both directions of rotation of the test). In the execution window, quantified results of each curve will be displayed. The test will automatically be accepted or rejected according to results of these 2 curves.

5. Test acceptance.

The software uses mainly 3 criteria (for each direction of rotation, that is to say 6 in total) in order to accept or reject the test:- The average of the curve: must lie between 84 and 103,5.

- The maximum of the curve: must be lower than (real average + 15,5%).

- The minimum of the curve: must be higher than (real average - 15,5%).

6. Other affected tests.

If the tension of the belts of the 135 Film carrier is modified in significant proportions, the following tests should be redone: :

- 135 cal play.

- 135 Hoffset.

- 135 cal encoder 2.

- 135 cal RGB IR.