1. Test overview.

This test is used to check that the subset " encoder wheel + sensor " of the film carrier functions correctly, and this in both directions of the motor.For that, the motor will turn in one direction in order to rotate the encoder wheel 6 times, then the same thing in the opposite direction. An analysis of the values registered by the encoder will allow to know if this subset functions correctly.

If this subset does not function, it is the whole of ADDR system which will stop working

2. Test conditions.

This test relates to the 135 Film carrier inserted in the scanner.The 135 Film carrier must be inserted in the scanner to carry out this test.

No film is necessary for this test.

The acceptance of the test is automatic.

No parameter is saved.

3. Pre-requirements.

The encoder wheel must be in the centre of the sensor, and must not touch this one. It is necessary to check that the encoder wheel is not buckled.

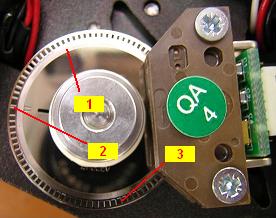

Explanation on the encoder wheel : The encoder wheel is used in the film carrier 500 signals per rotation (1), which indicates the precise position of the film + 1 signal per rotation (2) which indicates that one rotation has just been done (1 rotation corresponding to X mm in linear advance of film). The outside positions of the wheel (3) are not used..

4. Test realisation.

Click on RUN for executer the test. The moteur will turn during a few seconds in one direction then a few seconds in opposite direction. This length of time corresponds in fact to 6 rotations of the encoder wheel.At the end, curves will be displayed, corresponds to the 6 times 500 positions of the encoder wheel, in one direction then in the other.

5. Test acceptance.

Acceptance criteria are displayed on the screen (identical for each direction of operation):- Encoder polarity : Check of the direction of operation: must be OK.

- Encoder samples : Numbers of measurements (6 times 500): must be = 3000.

- Encoder variance : must be different from 0.

- Timings average : must lie between 1000 and 1500.

- Timings slope : must lie between -2 and +2.

6. Other affected tests.

- 135 Encoder 2.

- 135 Cal RGB IR.

- 135 ADDR.